CO₂ capture with MOFS

The Next Step in Carbon Capture

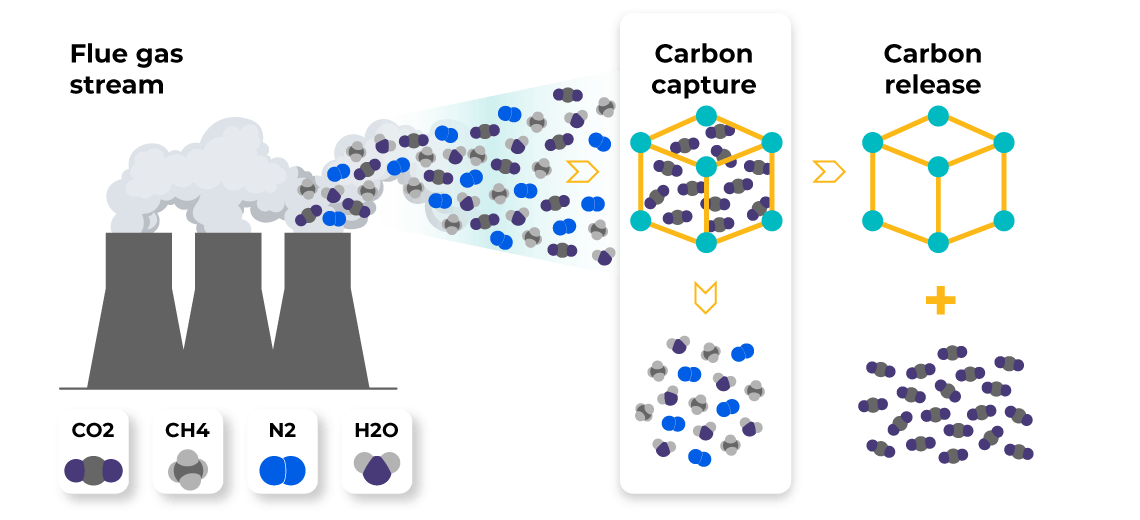

Carbon Capture, Utilization, and Storage (CCUS) is the integral strategy to fight climate change. Although there are different technologies for CCUS, adsorption using solid porous materials is a promising method owing to their high efficiency and relatively low energy consumption. Metal-Organic Frameworks have shown a remarkable capacity for storing small molecules, including CO2.

Mature carbon capture technologies such as liquid Amine scrubbing are intended to be substituted since they require high energy inputs. Adsorption technology using solid porous materials is a viable alternative. Recently, adsorption with porous materials has reached comparable performance to liquid amines through MOFs.

Post-combustion carbon capture is challenging due to the low pressure of flue gas streams and their high humidity levels. For this application, MOFs can achieve stable performance comparable to those of liquid amines, even in the presence of corrosive molecules such as SO2 and NO2.

The MOF’s outstanding uptake capacity and good selectivity are accompanied by low energy consumption, a critical feature for the industrial-scale application. MOF-based systems have the potential to decrease regeneration energy consumption by up to 2.7 times compared to well-established technologies such as amine absorption.

Relevant advantages of MOFs that promote their use as adsorbents for CO2 capture:

High CO2 working capacity

MOFs have a high working capacity, meaning that they can adsorb and then release a large amount of CO2 per cycle under realistic conditions. This working capacity is tunable for optimal performance under specific operating conditions.

Reduced energy requirement for regeneration

MOFs can be regenerated between cycles at relatively low temperatures. Using high temperatures for regeneration increases energy consumption and also limits productivity. MOFs allow lower temperatures to be used, leading to energy savings and improved productivity. It is even possible to regenerate MOFs using low-grade waste heat.

Performance in the presence of humidity

MOFs have been shown to selectively adsorb CO2 over multiple cycles even in the presence of high humidity. This is an advantage of MOFs over other adsorbents such as Zeolites and can allow for time and energy-consuming pre-drying steps to be avoided.

Tuneable adsorption behaviour

Due to their modular nature, the properties of MOFs can be optimized for best performance within a specific process system. 1000’s of potential metal and linker combinations can be used to design a MOF with the desired properties.

Favourable adsorption/desorption kinetics

MOFs are able to adsorb and desorb gasses quickly meaning that more process cycles can be performed within a given time. This, combined with MOFs low energy requirements for regeneration can lead to significant improvements in process productivity.

CO2/N2 selectivity

MOFs have exceptionally high CO2/N2 selectivity. This allows for improved productivity, recovery, and energy consumption as part of the CO2 separation process, compared to traditional adsorbents such as activated carbon and Zeolite.

We pioneer one of the world’s first industrial, high-performance CO₂-capture MOFs, enabling technology providers to build compact and sustainable systems for industrial emitters.

Case Study

Carbon Capture

MOFs are the ultimate solution for Carbon Capture thanks to their high adsorption capacities, excellent cycle stability, tunable selectivity, and energy efficiency.

Discover the capabilities of MOFs!

Key points covered:

- Different strategies for Carbon Capture

- Current technologies for post-combustion Carbon Capture

- Advantages/Disadvantages of the different capture technologies