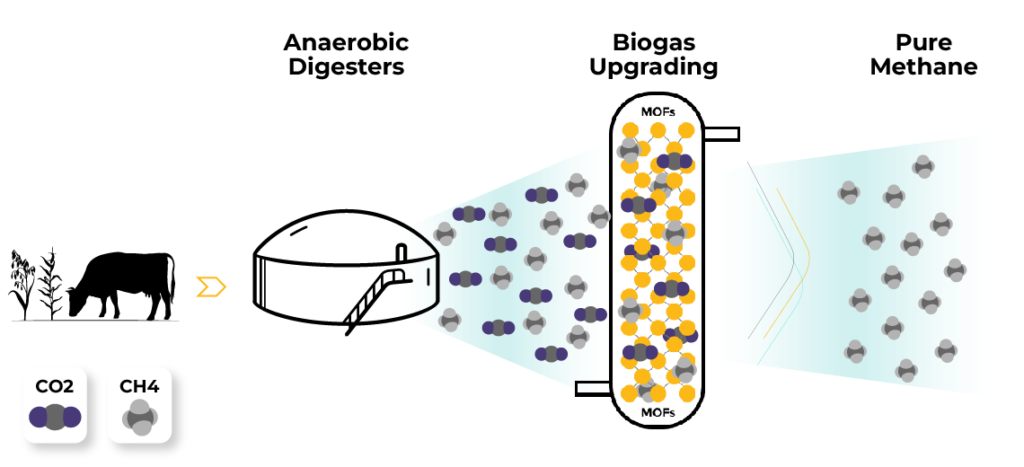

Biogas upgrading

Biogas is considered a greener fuel since it contains a higher hydrogen-to-carbon ratio than other fuels, and its combustion leads to reduced carbon dioxide emissions. Biogas requires a purification process (known as biogas upgrading) to allow its direct use in combustion engines, gas turbines, or fuel cells.

The most crucial advantage of MOFs compared to their counterparts (activated carbon and zeolites) is the ability to fine-tune their composition through a change of the metal center or the organic ligand. MOFs like MOF-74, MOF-505, and Cu3(BTC)2 show extremely high CO2 capacities at low pressure (1 bar).

The selectivity for gas separation in porous materials is related to several factors, including molecular sieving, thermodynamic equilibrium, and kinetics. Besides the high porosity of MOFs, their high tunability allows adjusting features like pore size, channel topology, and inner surface properties, enhancing the selectivity of the adsorbent material. Studies showed that the adsorption selectivity of 4-6 for CO2 over CH4 at a pressure range of 0.1-3 bars and a high CO2 adsorption capacity (6.6 mmol/kg at 2.5 bars and 30 °C) could be achieved by the implementation of MOFs.

The implementation of MOF-based adsorbents is a promising alternative with separation efficiencies of up to 98% of methane. Besides the excellent performance of MOF-based systems used for biogas upgrading, the CO2-rich stream can be used for reutilization to enrich greenhouse facilities and increase plant growth, improving crop production.

Relevant advantages of MOFs that promote their use as adsorbents for biogas upgrading:

High CO2 or CH4 working capacity

MOFs have a high working capacity, meaning that they can adsorb and then release a large amount of the target gas per cycle under realistic conditions. This capacity can be tuned to target specific separation demands such as CO2/CH4, CO2/N2 and CH4/N2

CO2/CH4/N2 selectivity

MOFs have exceptionally high and tuneable selectivity, this allows for improved productivity, recovery and energy consumption as part of the gas separation process, compared to traditional adsorbents such as activated carbon and Zeolite. The CH4/N2 selectivity of MOFs for biogas upgrading can typically be 2-6x greater than zeolite, activated carbon and mesoporous silica

Tuneable adsorption behavior

Due to their modular nature, the properties of MOFs can be optimized for best performance within a specific process system. MOFs can be tuned for optimal separation performance from the target gas mixture with the relevant component composition

Blog

Biogas upgrading

In the light of the world energy requirements for cleaner sources, the use of biogas has been raised as a promising alternative. Since biogas contains a higher hydrogen-to-carbon ratio, its combustion leads to reduced carbon dioxide emissions than fossil fuels.

Key points covered:

- Why does CO2 need to be removed?

- Alternative CO2 capture technologies

- Benefits of MOFs for biogas upgrading